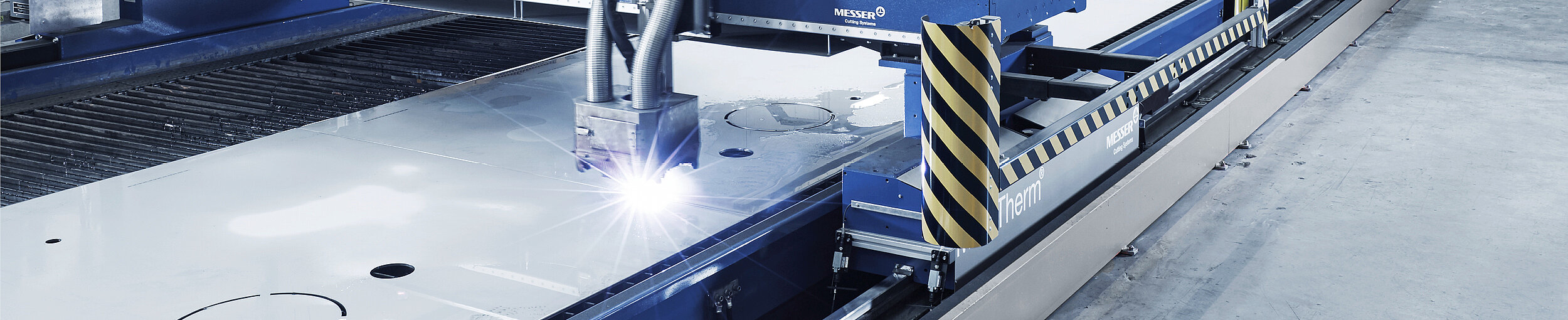

Plasma cutting of stainless steel is one of the most frequently used technologies in sheet metal working. Depending on the machine used for plasma cutting, this technology can be used to separate plates up to 150 millimeters thick. Our headquarters in Netphen-Deuz (Siegen-Wittgenstein district) are home to a powerful plasma cutting machine. We produce around 3.000 tons of stainless steel a year with plasma cutting. The maximum dimensions of the stainless steel plates that we can process on our plasma cutting machine are 12,000 x 4,000 x 150 millimeters. Our plasma cutting machines deliver a consistently high quality of cut and low cut angles.

Process for stainless steel cuts

Besides plasma cutting, we have the necessary know-how and technology to produce all established variations of stainless steel cuts. The method used depends on different factors, such as material thickness or subsequent use.

What is plasma cutting?

Plasma is an electrically conductive gas at a temperature of around 30,000 degrees Celsius. Plasma cutting triggers a thermal melting process in which the metallic material is melted in the kerf by the plasma jet and the molten metal is then blown out of the kerf at high pressure with inert gas.

What are the benefits of Plasma cutting?

Stainless steel cutting by plasma cutting is an effective and cost-efficient process that can convince with a high working speed. At the same time, it succeeds in cutting even strong materials. When inert gases are used, clean cuts are produced that have only a slight burr and hardly any slag buildup. Although the heat generated by the plasma is extremely high, the stainless steel to be cut hardly heats up at all. Experience and state-of-the-art technology have a great influence on the work result in plasma cutting.

und wählen Sie die Option Zum Home-Bildschrim.

und wählen Sie die Option Zum Home-Bildschrim.